PERFORMANCE You Can Trust • EFFICIENCY You Can Maintain

EXPERIENCE You Can Depend On!

BOILERS TO FIT ALMOST EVERY APPLICATION & BUDGET

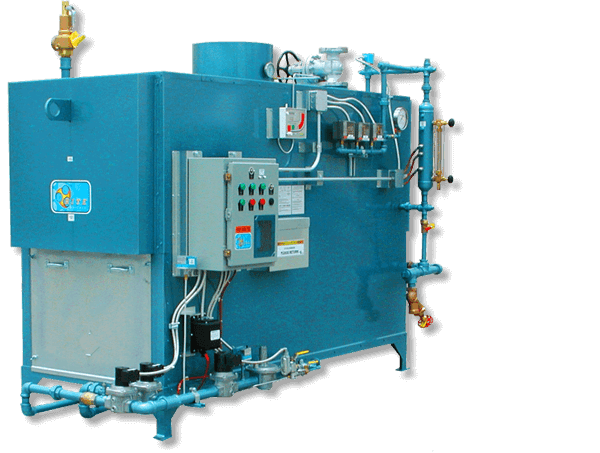

HIGH PRESSURE

STEAM (150PSI)

From food processing to textiles, hospitals to industrial process manufacturing - these heavy duty watertube steamers are available in sizes from 9.5 to 250 Boiler Horsepower.

MORE>>

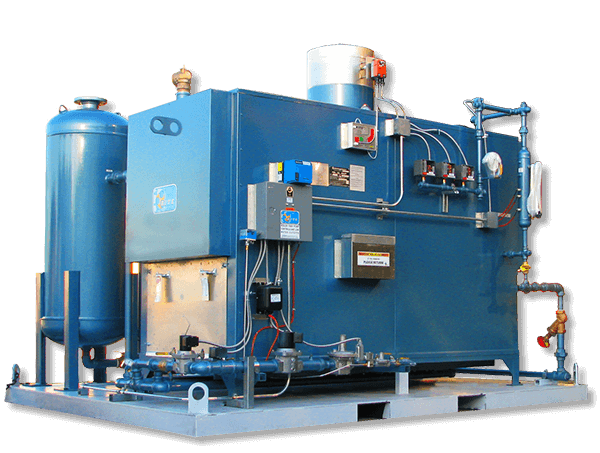

LOW PRESSURE

STEAM (15PSI)

From autoclaves to humidifiers, bakeries to breweries - these heavy duty watertube steamers are available from 4 to 300 Boiler Horsepower.

MORE>>

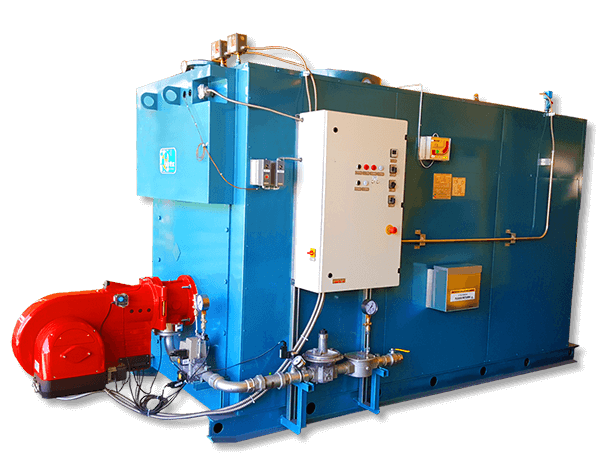

CONVENTIONAL

HOT WATER (125PSI)

From conventional space heating systems to heat pumps to industrial process loads, atmospheric or power burners from 480mbh to 12,500mbh.

MORE>>

HIGH EFFICIENCY

HOT WATER (160psi)

These near-condensing boilers are built with steel fintubes and designed to last a lifetime. They are 100% field repairable and warrantied for 25 years against thermal shock.

MORE>>

We have your industry covered ... that's RITE!

Rite boilers are a perfect fit for food and beverage producers. Our low pressure steam boilers have long been the boiler of choice for craft breweries, distilleries and food product companies.

Whether you are extracting essential oils, producing feed or drying nuts Rite has a boiler for you. boiler. Our boilers allow for complete cleaning and water side inspection. This is critical if your water source is less than optimal.

You will find Rite boilers anywhere a dependable heat source is required. Our boilers are used in industrial paint booths, galvanizers, and many other finishing applications.

READ MORE ABOUT STEAM BOILERS>>>

READ MORE ABOUT HOT WATER BOILERS>>>

If you are replacing an old boiler or designing a new building we have the equipment for all of your non-condensing applications. We offer the high efficiency hot water boilers and easy to maintain low pressure steam boilers. We offer the perfect replacement for old cast iron and firebox boilers.

READ MORE ABOUT LOW PRESSURE STEAM BOILERS>>>

READ MORE ABOUT HOT WATER BOILERS>>>

We have been providing boilers for these critical care facilities for over 50 years. As building technology has changed, the requirements for dependable steam or heating water has not. Our boilers are a perfect choice when efficiency, reliability and the ability to use fuel oil as a back-up is critical.

READ MORE ABOUT STEAM BOILERS>>>

READ MORE ABOUT HOT WATER BOILERS>>>

Rite Boilers can build a slip in replacement for most retiring Ajax or old firebox boilers. Contact your local rep for details.